When it comes to industrial operations, cleanliness is crucial to maintaining high performance, longevity, and quality standards. Whether you’re in automotive manufacturing, electronics assembly, or food production, ensuring your components are free of dirt, oils, and contaminants is essential. Industrial component cleaning machines play a vital role in various manufacturing processes. They are specifically designed to cleanse and degrease parts before assembly or usage. An industrial part washing machine is designed to provide an efficient, thorough cleaning process for a wide range of parts and products. But how do you choose the best one for your needs? This guide will walk you through the key considerations to make an informed decision, with insights into how Aplomb Machines India Private Limited can help you find the right solution.

Understand the Cleaning Requirements

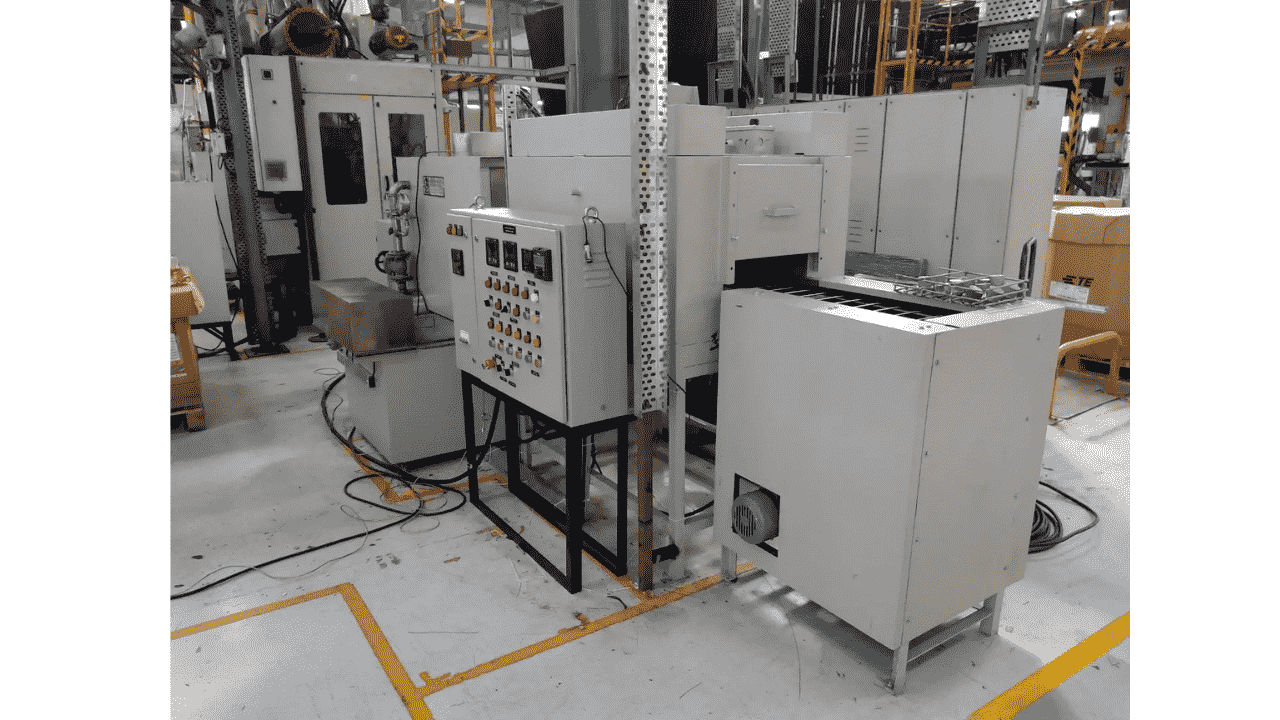

An industrial parts washing machine is a specialized machine designed for cleaning and removing contaminants from industrial parts, such as machinery components, gears, and other components. These machines typically use a combination of water, detergent, and high-pressure jets to blast away dirt, grime, and other contaminants. They can also include ultrasonic cleaning capabilities for removing hard-to-reach contaminants. Some industrial parts washing machines are also equipped with drying systems to remove excess water from the cleaned parts. These machines are commonly used in manufacturing, automotive, and aerospace industries. Different components require different cleaning methods, depending on their material, size, and the type of contaminants you need to remove. The following questions can help you define your needs:

What type of contaminants need to be removed? Consider oils, dust, dirt, grease, and other residues. Some machines are more effective at removing specific contaminants than others.

What materials are your components made of? Components made of metals, plastics, ceramics, or composites may require specific cleaning techniques.

What is the size and shape of the components? If you work with small, delicate parts or large, heavy components, you’ll need to choose a machine capable of handling these specifications.

What are the cleanliness standards? Different industries have varying standards, such as ISO cleanliness grades. Ensure the machine can meet the required level of cleanliness for your industry.

Types of Industrial Component Cleaning Machines:

The market offers several common types of industrial component cleaning machines, including:

Cabinet washers: Ideal for cleaning small parts in batches, these machines employ a combination of water, detergent, and agitation to eliminate dirt and debris effectively.

Drum washers: Designed for larger parts, drum washers utilize a rotating drum to agitate the parts within a cleaning solution, ensuring thorough cleansing.

Conveyor washers: These machines facilitate continuous cleaning by utilizing a conveyor belt to transport the parts through a cleaning solution, making them suitable for high-volume applications.

Ultrasonic washers: Using ultrasonic waves, these machines excel at cleaning small and intricate parts by effectively removing dirt and debris.

Benefits of Using Industrial Component Cleaning Machines:

Improved Efficiency: Automated machines clean parts faster and more thoroughly than manual methods, boosting overall productivity.

Consistent Quality: Ensures uniform cleaning, meeting quality standards without human error.

Improved part quality: Thorough cleaning removes contaminants, leading to higher quality parts with reduced defects and improved consistency.

Increased productivity: Efficient cleaning processes reduce cleaning time, allowing workers to allocate more time to crucial tasks like assembly or manufacturing.

Extended Part Life: Removes contaminants that could cause damage, prolonging the lifespan of components.

Customizable: Flexible designs allow businesses to tailor machines to specific cleaning needs.

Regulatory Compliance: Helps meet strict industry cleanliness standards for precision and safety.

Industrial component cleaning machines are indispensable tools in the manufacturing industry. They contribute to improved part quality, increased productivity, cost reduction, and enhanced safety. When selecting the appropriate machine, it is essential to evaluate specific application requirements and consider factors such as size, dirt levels, desired cleanliness, and budget.

Consider the Machine’s Capacity

The capacity of the cleaning machine is another important factor. This depends on how many parts you need to clean and their size. The larger the machine, the more parts you can clean at once, which increases productivity.

- Batch Cleaning vs. Continuous Cleaning: Batch cleaning systems are designed to clean a set number of parts at a time, while continuous systems can clean parts as they move through the system. If you have high throughput needs, a continuous cleaning machine may be the better option.

- Size of Parts: Ensure the machine is large enough to accommodate your largest components. Some machines offer customizable sizes or adjustable racks to fit a variety of components.

Assess the Operating Cost and Maintenance

Cost is always a factor when purchasing new equipment. Industrial part washing machines can be expensive, but it’s important to evaluate the long-term costs, including:

- Energy Consumption: Machines that use heated solutions or high-pressure systems can be energy-intensive. Consider the operational costs associated with these systems.

- Consumables: Many machines use cleaning solvents, detergents, or ultrasonic cleaning solutions, which may need frequent replenishment.

- Maintenance: Machines with complex mechanisms, such as ultrasonic cleaners or vapor degreasers, may require more frequent maintenance and replacement of parts. Ensure that the machine you choose is easy to maintain and has good service support.

5. Look for Automation and Integration Features

Automation can significantly improve the efficiency of your cleaning process. Some industrial part washing machines are equipped with automated features, such as:

- Loading/Unloading Systems: Automated loading and unloading can increase throughput and reduce labor costs.

- Control Systems: Advanced control systems allow for easy programming and monitoring of the cleaning process, improving consistency and reducing human error.

- Data Logging: Some machines include data logging and reporting features to track cleaning cycles, temperature, solvent usage, and other critical data.

Integration with your existing manufacturing equipment can streamline the entire process, making your operation more efficient and reducing potential bottlenecks.

6. Consider Environmental Impact

Environmental concerns are becoming more important than ever. It’s essential to choose a cleaning system that aligns with sustainability goals. Look for machines that minimize water and chemical use, use environmentally friendly detergents, and have waste disposal systems in place. Additionally, machines that meet regulatory standards, such as ISO 14001, can help ensure compliance with environmental regulations.

7. Evaluate the Manufacturer’s Reputation and Support

Lastly, consider the reputation of the manufacturer. A reliable manufacturer, like Aplomb Machines India Private Limited, can provide strong customer support, good warranties, and easily accessible spare parts. Look for user reviews, testimonials, and case studies that demonstrate the machine’s effectiveness in your industry. Aplomb Machines India is known for delivering high-quality industrial part washing machines that cater to diverse industries, offering solutions that balance efficiency and sustainability.

Conclusion

Choosing the right industrial part washing machine requires a thorough understanding of your needs, cleaning methods, and machine features. By evaluating the contaminants you need to remove, selecting the right cleaning method, considering capacity and cost factors, and ensuring the machine fits into your workflow, you can make an informed decision. Aplomb Machines is committed to maintaining high-quality standards in its manufacturing processes. We are also known as leading manufacturer and supplier of high-quality Leak Testing Machine in India. We specialize in providing advanced, reliable, and efficient leak testing solutions designed for various industries, including automotive, aerospace, and manufacturing. Our leak testing machines ensure accurate detection of leaks in components, ensuring product quality and safety. This dedication to quality has earned Aplomb a loyal customer base and numerous successful projects completed over the years. With the right cleaning machine, you can improve efficiency, meet industry standards, and extend the lifespan of your components, ultimately boosting your productivity and profitability. A trusted manufacturer like Aplomb Machines can guide you through the process and provide the ideal cleaning solution for your needs.