Broaching Machine Manufacturer

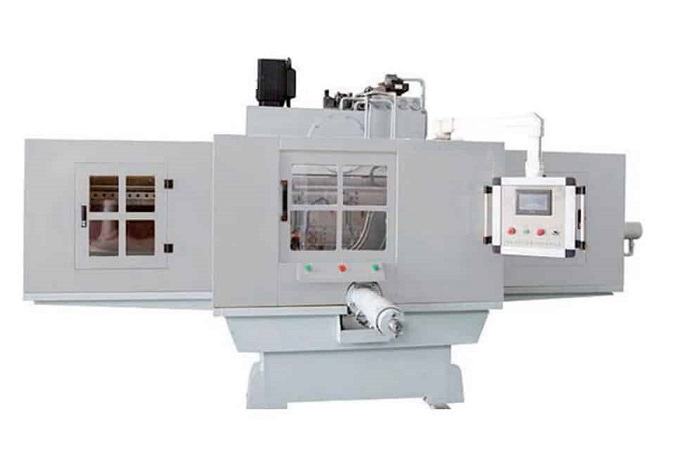

Aplomb Machines India Private Limited is a leading manufacturer, supplier, and exporter of broaching machine, vertical and horizontal Broaching Machine, hydraulic broaching machine, and broaching gear machines in Ghaziabad, Uttar Pradesh, India.

An industrial tool used for precise metal cutting and shaping is called a broaching machine. It uses a special process called broaching, which is the removal of material using a toothed cutting tool called a broach. The machine has a linearly moving broach mounted vertically or horizontally, which cuts and forms different shapes like keyways, splines, or gears. CNC broaching machines are effective for high-precision tasks and are commonly found in the manufacturing, automotive, and aerospace industries. They provide benefits like increased productivity, accuracy, and consistency when producing complex metal components, making them essential in today’s manufacturing processes.

What is vertical broaching?

Vertical broaching refers to the type of machine that is used to broach a piece of metal. Vertical broaching is typically used to cut external slots, shapes, and forms. Each application of vertical broaching usually consists of a custom-made tooling package and a fixture to hold and secure the piece. An example of a vertical broaching application would be cutting a deep slot in a large industrial valve stem.

Aplomb Machines India Private Limited has a wide variety of vertical broaching machines, each machine distinguished by its stroke, which defines the length of cut, and its power, which defines the size of cut the machine can make.

Our Products

Fill Up The Form

Vertical Broaching Services

- 5 vertical broaching machines

- 90-inch maximum cut length (in one pass)

- 10-ton maximum cutting power

- Two dual-ram machines capable of cutting two parts at once, or two operations on the same part

- The ability to cut virtually any machinable material, including stainless steel, plastic, magnesium, and powdered metal

- In-house tooling department, capable of manufacturing, sharpening, and reconditioning your tools, to preserve tool integrity and longevity

What Are The Advantages of Vertical Broaching?

- Typically faster than traditional horizontal broaching methodology, without compromising the length or size of the cut

- Machinery can be specifically matched to the part being cut, for a more efficient cutting operation

- It is well suited for cutting external shapes and forms quickly, while still holding close tolerances

- Extremely economical cutting process, very often superior to milling

- Tooling can be modular in design, allowing for variations of the same basic cutting pattern

- Different cutting operations can be optimized on the same dual RAM machine

Vertical broaching machine come in many varieties and adaptations, but in general, any machine in which the ram is mounted vertically, instead of horizontally, is classified as a vertical broaching machine. In the case of surface broaching, the ram, which carries its broaching tools mounted in holders, typically moves past the piece. The piece is secured in a fixture using hydraulic or mechanical clamps. Some traditional vertical broaching machines are dual ram, meaning that there are two rams mounted on the same machine, and sharing the same hydraulic and mechanical systems. In many cases, the part is secured on a shuttle table or swing table so that the operator can load one piece to be machined, while the other ram is cutting another piece at the same time. Dual ram vertical broaching machines can also be used to cut two or more successive operations on the same part.

Vertical broaching machines can also be used to cut internal shapes and forms and can perform very much like traditional horizontal machines. In each case, either the piece part is secured while the broaching tool moves past it, or the broach itself is secured while the piece part travels on a table. The former type of machine can be either the vertical pull-down or pull-up variety (referring to the motion of the broaching tool). The latter is typically referred to as a table-up vertical broaching machine.

What is a Broach Machine

A broach machine is a specialized tool used for broaching, a machining process that removes material from a workpiece to create precise shapes and finishes. This machine employs a long, multi-toothed tool called a broach, which is pulled or pushed through the material to achieve the desired contour.

| Brand | Aplomb India |

| Maximum workpiece diameter | 340 mm |

| Cutting speed | 1 to 10 m/mm |

| Weight of machine | 2450 Kg |

| Maximum stroke | 1320 mm |

| Maximum pulling force | 5000 kg |

| Return Speed | 30 m/mm |

| Maximum broach diameter | 60 mm |

| Total power necessary | 6.5kW |